VOCs處理 - 模組化設備

Thermal Oxidizer

首頁 » Thermal Oxidizer

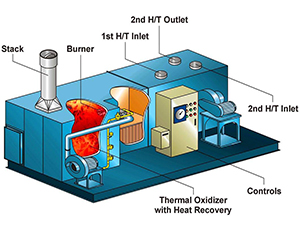

Thermal Oxidizer (Recuperative) – T.O

換熱式氧化爐設計特點

換熱式熱氧化器可以應用於幾乎所有蒸氣態的可燃有機污染物。 氧化器幾乎可用於任何行業,但通常用於化學、製藥、印刷、塗料、造紙、紡織和油漆塗飾的應用。

當多餘的熱能可以回收用於生產過程的其他地方時,換熱式氧化器單元是最經濟的。 當進入的溶劑濃度高時,氧化器的運行成本更低,因此需要的燃燒器燃料就會比較低。

RECUPERATIVE DESIGN FEATURES

Recuperative thermal oxidizers can be applied to almost all combustible organic pollutants in a vapor state. The oxidizers are applied in virtually any industry, but can oft en be found in chemical, pharmaceutical, printing, coating, paper, textile and paint finishing applications.

Recuperative oxidizer units are most economical when excess thermal energy can be recovered for use elsewhere in the production processes. Recuperative oxidizer operating costs are lower when the incoming solvent concentration is high, so less burner fuel is required.

MICRO-RECUP 8,000 SCFM, WOOD PRODUCTS INDUSTRY

RECUPERATIVE THERMAL OXIDIZER

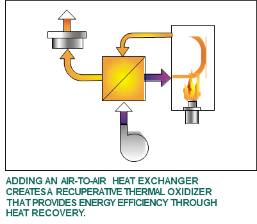

This type of oxidation technology uses a conventional type of heat exchanger to preheat the incoming air with air from the oxidation process.

- Integral primary heat recovery up to 83%

- Secondary heat recovery available

- Dedicated combustion air supply

- 99% VOC destruction efficiency

- Refactory lined combustion chamber

換熱式氧化爐

這種類型使用傳統的氧化技術用於預熱製程氣體與來自氧化過程的空氣熱交換器類型。

- 整體一次熱回收率高達 83%

- 可進行二次熱回收

- 專用助燃空氣供應

- 99% 的 VOC 破壞效率

- 耐火內襯的燃燒室

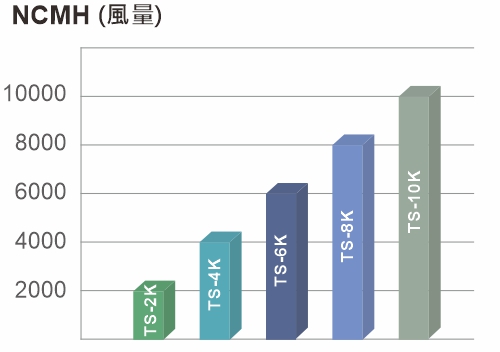

| TYPE | NCMH | L (mm) | W (mm) | H (mm) | Weight (KG) |

| TS-1000 | 1000 | ||||

| TS-2000 | 2000 | ||||

| TS-3000 | 3000 | ||||

| TS-4000 | 4000 | ||||

| TS-5000 | 5000 |