VOCs處理 - 模組化設備

VOCs Concentrator Rotor

首頁 » VOCs Concentrator Rotor

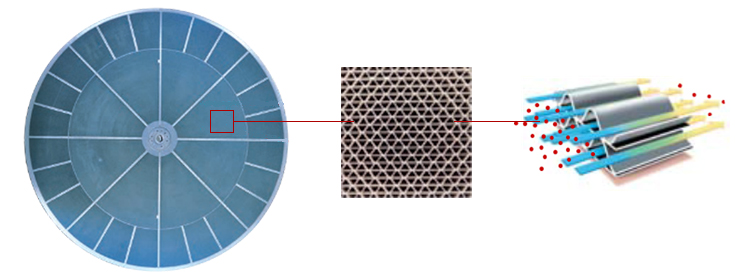

VOCs Concentrator Rotor (HAR)

在處理大風量的低濃度VOCs廢氣時都需要大型設備,大大增加了初始成本和運行成本。

通過使用VOCs Concentrator Rotor,可以將大風量含有低濃度的VOCs廢氣濃縮為高濃度的低風量,高效的處理含有 VOCs 的廢氣。

VOCs Concentrators Rotor Disk Type

Choices of Adsorption Media

- Match the adsorbent media to the emissions in the process

- Zeolite vrs. Carbon

– Complimentary Rather Than Competing Technologies

- Structural Differences

- Applications Differ

- Adsorption Characteristics Differ

Removal Efficiency relates how:

VOC is transferred from large air volumes to adsorbent media prior to exhausting to atmospher

如何涉及去除效率:

VOC 在排放到大氣之前從大風量轉移到吸附介質

Concentration Technology

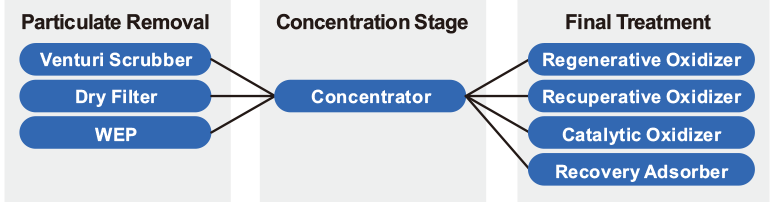

Concentrators are CAPTURE Devices

- VOC are removed from process air by adsorption

- Adsorption media is continuously regenerated

- VOC destruction after concentrator becomes very economical

濃縮技術

集中器是捕獲設備

- 通過吸附從製程空氣中去除VOC

- 吸附介質不斷再生

- 經由濃縮器後的VOC銷毀變得非常經濟

Suitable Applications for Concentrators

High air volume – low VOC concentration

VOC Concentration <800-900 ppm

- Process exhaust temperature <120°F

- No resin, heavy metals, or oils present

- No halogenated compounds present

- No sulfur compounds present

適用於集中器的應用

高風量-低VOC濃度

VOC 濃度 <800-900 ppm

- 工藝排氣溫度 <120°F

- 不含樹脂、重金屬或油

- 不存在鹵化化合物

- 不存在硫化合物

| Type | Process air flow amount ( N㎥/min )*1 | Type | Process air flow amount ( N㎥/min )*1 |

| SCB-1220 | ~200 | SCB-2650 | 650~900 |

| SCB-1525 | 180~300 | SCB-2950 | 850~1100 |

| SCB-1740 | 250~400 | SCB-3250 | 1000~1300 |

| SCB-1940 | 350~500 | SCB-3550 | 1200~1600 |

| SCB-2190 | 450~600 | SCB-3850 | 1400~1900 |

| SCB-2450 | 550~750 | SCB-4200 | 1700~2300 |

| ADSORBENT | WHAT IT ADSORBS |

| Carbon | Removes xylene and most common paint solvents. Ineffective at removing methanol. |

| Zeolite with 6Å pores | Removes methylene chloride, methanol and most low-molecular-weight solvents. Somewhat less effective with xylene and solvents larger than 6Å diameter. |

| Zeolite with 8Å pores | Removes higher-molecular-weight solvents. |

| Carbon and zeolite in a series | weight solvents. Removes solvent mixtures containing moderate amounts of methanol (15% to 25%) at low total VOC loadings (less than 250 ppm). Note that a physical mixture of carbon and zeo-lite on a single substrate is more effective than the two in series at removing high concentrations of solvents (>300 ppm) with lower (<20%) alcohol contents. |

Å = angstrom. 1Å = 1×10-10 meter

| Type | Process air flow amount ( N㎥/min )*1 | Dimensions ( mm ) *2 Length × width × height ( L × W × H ) | Estimated weight ( tons ) *2 |

| SCB-1220 | ~200 | 2100 × 1550 × 1650 | 1.2 |

| SCB-1525 | 180~300 | 2100 × 1850 × 1950 | 1.5 |

| SCB-1740 | 250~400 | 2100 × 2050 × 2150 | 1.6 |

| SCB-1940 | 350~500 | 2100 × 2250 × 2350 | 1.7 |

| SCB-2190 | 450~600 | 2100 × 2500 × 2600 | 2.6 |

| SCB-2450 | 550~750 | 2100 × 2800 × 2925 | 3.0 |

| SCB-2650 | 650~900 | 2100 × 3000 × 3125 | 3.5 |

| SCB-2950 | 850~1100 | 2100 × 3300 × 3525 | 4.0 |

| SCB-3250 | 1000~1300 | 2100 × 3600 × 3850 | 4.6 |

| SCB-3550 | 1200~1600 | 2100 × 3900 × 4150 | 5.2 |

| SCB-3850 | 1400~1900 | 2100 × 4200 × 4450 | 5.8 |

| SCB-4200 | 1700~2300 | 2100 × 4550 × 4800 | 7.0 |